Pogue Carburetor, 'Gasoline Vapor Maker' Increase Mileage

Charles Nelson Pogue invented a carburetor that vaporized gasonline, instead of nebulizing it into tiny drops, thus dramatically increasing mileage per gallon of gasoline used. Like so many other inventions, that carburetor did not fit in with the business plans of those in the auto and oil industries. It was bought and shelved, leaving enthusiasts to try and make their own ... if they had the specialized knowledge and tools to do so.

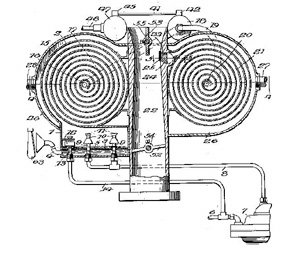

Pogue Carburetor - patent illustration.

A press report from that time reads as follows:

Double-Mixing Carburetor Increases Power and MileageA NEW carburetor that makes mileage of 200 miles per gallon a possibility has been invented by a Winnipeg, Can., engineer. It has been tested and examined by several automotive engineers who claim it is entirely feasible in its action.

C.N. Pogue, the inventor, supplies his carburetor with two mixing chambers instead of one. The gasoline is vaporized in the primary chamber and before being used is sent through another mixing chamber. Here, since it is vapor that burns and not liquid gasoline, the gasoline is further vaporized into a still finer mixture. This insures more power and mileage from usual quantity of liquid gasoline.

It sounds strange that such an invention could be kept off the market and that our cars still guzzle as much gasoline by the mile as they did back then. Pogue developed his carburetors in the 1930s. He took out three patents between 1930 and 1936. All three of these can be found on the excellent site of Rex Research as part of an article titled "Oil Industry Suppressed Plans for 200-mpg Car".

I reported in 2003, that the original blueprints for such a 200 mpg carburetor had been found in England. The story attracted much attention and a huge number of comments - both in favor and against. A lot of people seem to experiment with the idea, so I decided to come back to it.

The fact that carburetors that vaporize gasoline bring more mileage than the old kind and may even be better than direct injection has been confirmed by Frank, who contacted me and offered his own take on Pogue, as well as his plans for a Gasoline Vapor Maker. Frank - it's not his real name - does not want to put his neck out too far, but he does have interesting things to add to the story of the suppressed supercarburetor.

- - -

Pogue Carburetor Plans

(by Frank E.)

Approximately 1970, my dad sent me a copy of the patent for the Pogue carburetor, and asked me to make one. I studied it over very carefully, and after consulting with a mechanist friend, decided that with the current labor and material costs, it would be way too expensive, impractical, and probably not useable for today's engines.

As I studied the plans, I realized that there were several principles involved. The first was that gasoline in the liquid form does not burn. Nor does it explode. Only the vapor that comes from the gasoline will burn. Therefore, to mix raw gasoline with air, and attempt to explode it in an internal combustion engine is a very wasteful, costly, and polluting practice. It also shortens the life of the engine and exhaust system.

The carburetor systems on most, if not all the gasoline powered motor vehicles sold in North America, mix raw gasoline with air shortly before entering the combustion chamber. Enough raw gasoline must be used to insure that enough vapor is produced by the time the spark ignites the mixture so that the oxygen / fuel balance is proper. Too much oxygen will burn the valves. However, most of the raw gasoline is vaporized after the explosion is completely over with and what's left is on the way out through the exhaust system. To appease the EPA, the auto makers put on catalatic converters to burn up all the extra unburned gasoline vapor. Some of the raw gasoline also washes down the cylinder walls, and into the oil to be vaporized by the heat of the oil. The "smog valve" then returns it to the carburetor.

From what I've heard and witnessed over the years, I would estimate that there is enough potential in a gallon of gasoline to propel any full sized car or pickup, with the engines in common use, at least 100 miles, and some as much as 200 miles, all while driving normally. Why then only 8 to 30 miles per gallon? Simply because the auto manufacturers choose to use as much gasoline to power the nation's autos as the public lets them get away with. After all, why endanger the enormous economics wrapped around the petroleum industry.

If you want to get all the power out of your gasoline that you paid so dearly for, then you have to completely vaporize it before it is injected into the carburetor. All devices, if they do not completely vaporize the gasoline, are only swatting half heartedly at the problem.

Note: The preceding account, except for the first paragraph, was rewritten from literature I had written in 1970, or thereabouts. I simply made it more up to date. I must tell you that today's gasoline is much harder to totally vaporize before the combustion. The purpose of that is to thwart carburetors such as Pogue's or mine.

Charles Nelson Pogue - Image credit: Vapor Systems

After my dad had sent me that copy of the Pogue Carburetor patent, and while I was working on my plans, an old retired gentleman with whom I was acquainted, came into my shop, and began to tell me of his experiences. He had been a mechanist somewhere in Minnesota I think, when a French Canadian came to the shop. The Canadian had invented a carburetor, but was having trouble with it vapor locking. The mechanist designed a valve for him that solved the problem. While the mechanist was talking, he kept saying, "Oh, what was his name? Oh, what was his name?" I finally ask him, "Was that valve shaped like a rod split in half?" He looked at me in amazement, "Why, yes! How did you know?" I asked another question, "Was his name Pogue?" Then the old man was really amazed that I knew. I showed him the copy of the patent that I had, and he was really excited. He went over the papers like an excited child.

The old machinist went on to tell me how several months or was it years later he had to take some paperwork up to the main office. He had to go through the conference room where he saw Mr. Pogue in the midst of a bunch of oil company big wigs. He named the wigs, but I forget the names. They were heads of Texaco, Shell, Esso, etc. Some of them had red faces, and Mr. Pogue looked like a trapped rabbit. Of course the machinist was very interested as to what was going on, but he knew he wasn't supposed to be there, so he went on his way.

Later, one of the office boys came down to the shop, and told the machinist, "Hey, you know that Pogue guy that you made that valve for? Well, he sold that carburetor, and plans, lock stock and barrel to the oil company guys. They had a black man carry the whole thing down and put it into the trunk of a Pierce Arrow, and he drove off. That had been the last he had heard or seen of it until I showed him those patent papers.

After I had made my own plans, I confided in George Swartzendruber, an elderly friend of mine. One day he brought over an out of state friend of his who had been visiting. I was a little upset, because George had promised secrecy. However, when this friend had told me his story, I warmed up a bit, and showed him the plans - Pogue's, and also mine. The experience he had told me about was this: His uncle, who had lived in a northern, midwestern state, had been a good friend of Pogue. One day while he was visiting his uncle, Mr. Pogue drove up the farm lane, jumped very excitedly out of his car. "I have it! I have it!" He drained all the gas from his car's tank into a can, then poured 1 gallon back in. Then they drove all over the countryside for 60 miles on that one gallon of gas! The friend said, "Then Pogue went back up to Canada, and we never heard from him again."

I gave the out of state friend a copy of my plans, and he went on back home with it. Later, I heard through George that he had made it, but had been too scared to use exhaust to heat the evaporator, so instead he used water from the radiator. Well, it wasn't quite hot enough to do the vaporizing job completely. Periodically, he had to drain and waste the build up of liquid gasoline from the system. However, in spite of all the waste, he still netted 60 miles to the Gallon! Someone else up that way got about that much mileage until his truck caught on fire and burned up! Anyone else who does anything with these plans are totally on their own! I'll tell you my plans, but first, I'll scan in the Pogue Carburetor patent.

Let's all take our hats off to Mr. Charles Nelson Pogue. There's been a lot of high mileage carburetors, but I think he may have done it first. If you want to know what others have to say about the Pogue carburetor, just ask Google for "2026798 mileage" (without the "quote" marks) and take your pick of web sites.

Sepp's Note: Frank sent a copy of Pogue's patent, a scan of an old photocopy, not the clearest. But you can find the patents on other sites. One good link is on Rex Research. Should that link go bad, don't despair, there is a PDF copy here.

- - -

The Gasoline Vapor Maker

as described by Frank

Here are the plans which I drew up in about 1970. George's buddy from the midwest made one, and others have been made. So I advertised "The Gasoline Vapor Maker" in a national magazine. I sold a few. Then I got a nasty, threatening letter, and got cold feet. So I wrote to all the buyers and offered them their money back if they returned the plans. Two or three came back for refunds, the rest were kept by the buyers, who I never heard from again.

However, from that time on, everybody and his brother started advertizing my plans. Of course they were changed in an attempt to make it unrecognizable so that they wouldn't look like copies my plans. Now the cat was really out of the bag, and the petroleum industry couldn't threaten and scare that many people. Now what would the biggest industry in the world do to protect their money cow? Change the formula, that's what! Now, the additives in gasoline make it nearly impossible to vaporize until after the combustion. Just enough will vaporize for a correct mixture in the combustion chamber. The rest goes out the exhaust system to evaporate on the way out. Of course, by now, the EPA has stepped in in an attempt to cut down on pollution. They require most vehicles to have catalytic converters. However, if the gasoline was completely vaporized before the combustion, and burned in the combustion, the catalytic converter wouldn't have much to do. Not only that, catalytic converters don't prevent pollution, they only change it to a different form - for better or for worse!

Whatever you do with implementing these plans is totally at your own risk! I'm sure that someone else can come up with better plans. However, if you use my plans, someone else's, or come up with your own plans, know that there are dangers involved - from explosions, big money interests, or errors (as in "trial and error") As far as I am concerned, you are on your own. Have fun, but be very careful.

The Operation of THE GASOLINE VAPOR MAKER

The raw gasoline leaves the vehicle's gasoline tank (1) and goes through the first electric gasoline pump (2) and on to the atomizing chamber (11) where it is forced through the atomizers (4) and strikes the first baffle (10). What is not vaporized, then falls to the bottom of the chamber.

The three baffles (10) are slanted so that any droplets that form due to condensation will also run down to the bottom of the chamber (11). It should be possible to open and clean the chamber (11) periodically.

The raw (or liquid) gasoline level (7) in the chamber (11) is maintained slightly above the top of the standpipe (6) by the float and stopper(9) arrangement. When the liquid level (7) rises too high, the float raises the stopper (9) and the raw gasoline is allowed to go down the return pipe (3) to be recirculated through the first electric gasoline pump (2).Since it is easier for the pump (2) to draw raw gasoline from the return pipe (3) than from the gasoline tank (1), only that portion of raw gasoline that is actually vaporized will be drawn from the tank. A low pressure restriction valve (not pictured) may, in certain applications, be necessary in the line coming from the gasoline tank (1).

Air can, either freely or slightly forced (perhaps by the engine's radiator fan), enter the air inlet (8) to bubble up through the finely perforated screen (5) into the atomizing chamber (11) to mix with the raw gasoline droplets, helping them to form vapor.

The vapor then goes back and forth between the baffles (10) and finally enters heater (12) through the vapor pipes (13).The vapor heater (12) consists of large diameter pipe (like perhaps a four inch truck exhaust pipe two or three feet long) in which hot exhaust fumes from the vehicle's exhaust system flow through to keep it heated. The size and length of it is dependent upon the size and need of the engine. The exhaust fumes are then returned to the exhaust system. In this large pipe (12) is a series of small pipes (13) which carry the vapors back and forth many times through the vapor heater (12). These vapor pipes (13) may be anywhere from one half inch to perhaps one inch in diameter, whatever is necessary to carry sufficient vapor for the size of the engine. It might be helpful to use a spiral type of pipe such as is used for connecting heaters and stoves to natural gas outlets.

After going back and forth for a number of times, the vapor is then piped directly into the second electric gasoline pump (15) which can pump the vapor up to perhaps 20 pounds per square inch. It then returns directly to the vapor heater (12) to be piped back and forth some more.

The pressure of the vapor between the second pump (15) and the vapor valve (18) is maintained at a constant level regardless of how much or how little is actually allowed to enter the carburetor (24). This accomplished by the adjustable pressure relief valve (14). The higher you adjust the valve (14), the richer the air / vapor mixture in the carburetor (24), likewise, the lower you adjust the valve (14), the leaner the mixture.

The excess vapor that is forced through adjustable pressure relief valve (14), and is continually recirculated through the second electric gasoline pump (15) until it is actually used by the vehicle's engine.

After the vapor leaves the vapor heater (12) for the second time, it goes directly to the vapor valve (18) and then on to the carburetor (24).

Linked with it, the vapor valve (18) opens enough to let pass enough vapor to have a proper air / vapor mixture regardless of the position of the throttle valve (22). The linkage (26) should go between the throttle valve (22), and the vapor valve (18) to make them work in conjunction with each other. It should be adjustable.

Bypassing the vapor valve (18), is the idle mixture channel (17), which allows to pass enough of the vapor to maintain the proper vapor / air mixture while the engine is idling.. On the channel is the adjustable idle orifice (19) which can be adjusted for proper idle mixture. Between this channel and the vapor heater (12), is an electromagnetic valve (16) which remains in a closed position unless the ignition is turned on. The turning on of the ignition switch activates the valve (16) so that it is held on, allowing free flow of the vapor. Note: in some of the modern vehicles, the ignition can be turned on for auxiliary use even when the engine is not running. In these, a separate switch will have to be added. This switch could be hidden to prevent unauthorized use of the vehicle.

In the closed position, the electromagnetic valve (16) is so well closed, that absolutely NO vapor can escape through to cause a dangerous situation while the engine is not running.

The vapor enters the carburetor (24) through the specially drilled port (20) in the ventura below the throttle valve (22). A flash screen (23) is provided over the port (20) to prevent a backfire by the engine from igniting the vapor in the lines.

The choke valve (21) will operate in the same manner as in the original arrangement, except that automatic chokes may need a little adjustment. However, I doubt if a choke would actually be needed because the gasoline is completely vaporized.

The original float chamber (25) on the carburetor (24) is left intact except that the old gasoline line (27) that brings the raw gasoline from the tank (1) is disconnected. Both the line (27) and the float chamber (25) entrance are plugged.

If the Gasoline Vapor Maker should ever be removed from the vehicle, the port (20) may be closed over and the gasoline line (27) reconnected to put it back to the original operation, thus allowing the owner to install the Gasoline Vapor Maker on his next vehicle.

Early numbered drawing of Gasoline Vapor Maker

Later drawing of Gasoline Vapor Maker (not to scale)

- - -

In addition to these plans for his version of a Gasoline Vapor Maker, Frank sent a later version, which however was never made or tried. It is a variation of the first one, and is reproduced here for any experimenter out there who would like to try a different design.

As always, be careful. You alone are responsible for what you are doing.

The Gasoline Vapor Maker #2

This is a later version I had made, but it was never tried or proven. However, it might be a lot easier to make. Again, all the cautions and disclaimers apply. If you make this, you are on your own. Make sure your insurance is paid up. Remember that this is totally in the experimental stage, and you assume any and all the risk. View these drawings as a starter that can be redrawn by you into something better. This is not copyrighted or patented, so that big money interests can't buy it out of our hands. Let's keep it that way.

1. Gasoline Tank

2. Electric Gasoline Pump

3. Gasoline Line

4. Gasoline Line

5. Lock-off Valve

6. Check Valve (for Gasoline)

7. Gasoline Line

8. Vaporizing Tank

9. Lower Chamber of #8.

10. Upper Chamber of #8

11. Valve

11a. Standpipe

12. Float

13. Inlet Valve

14. Tube

15. Upper Gasoline Level

16. Lower Gasoline Level

17. Heating Coil

18. Check Valve (for Vapor)

19. Vapor Line

20. Vapor Pump

21. Vapor Line

22. Pressurized Tank

23. Pressure Relief Valve

24. Vapor Line

25. Atomizer Jet

25a. Alternate Location for Atomizer Jet

26. Pressure Relief Valve

27. Whistle

28. Emergency Relief Line

29. Vapor Line

30. High Pressure Regulator

31. Low Pressure Regulator

32. Lock-off Valve

33. Vapor Line to Carburetor

See drawing for Gasoline Vapor Maker #2

The Operation Of THE GASOLINE VAPOR MAKER #2

Note: All temperatures given are in Fahrenheit. All inches, etc. mentioned are in USA measurements. PSI is pounds per square inche as in USA pressure measures.

The liquid gasoline leaves the vehicle's gasoline tank (1) and goes to the electric gasoline pump (2) through line (3), then through line (4) to lock-off valve (5) and check valve (6) then through line (7) to inlet valve and float assembly (12 & 13) and into the vaporizing tank (8).

The vaporizing tank (8) is divided into two chambers, the upper chamber (10) and the lower chamber (9). The liquid gasoline sets in the bottom of the lower chamber (9) and is filled to upper gasoline level (15). It is then cut off from further filling by the float and valve assembly (12 & 13). It is heated by coils (17) until vaporized.

There is a valve (11) mounted on a hole on the sloping divider between upper chamber (10) and lower chamber (9). This valve (11) remains open for pressure equalization between the chambers (9& 10), but closes when pressure reaches 50 psi, (?) At which time the liquid gasoline remaining in the bottom of the lower chamber (9) is forced up tube (14) by the pressure in lower chamber (9) continuing to rise, thus bringing the liquid gasoline level down to the lower level (16). This insures that too much vapor is not made, thus bringing the pressure too high.

Vapor is then pumped through check valve (18) and vapor line (19) by the electric vapor pump (20), on through vapor line (21) into the pressure tank (22). PLEASE NOTE: It may be better to install check valve (18) in vapor line (21) between vapor pump (20) and pressure tank (22), rather then in the vapor line (19) as shown in the drawing.

When the vapor pressure in pressurized tank (22) reaches 80 or 90 PSI, some pressure escapes through the pressure relief valve (23) and line (24) and is broken up into many small streams of vapor by the atomizing jet (25) further vaporizing the liquid gasoline in bottom of chamber (9). An alternate location (25a) for the atomizing jet (25) can continue to vaporize the liquid gasoline after enough has already been vaporized.

Another purpose for the pressure relief valve (23) is to remove from pressure tank (22) liquid gasoline that has condensed. This is why valve (23) is located in the bottom of tank (22).

In the event of a malfunction of pressure relief valve (23) or any other malfunction that would cause the pressure in the pressurized tank (22) to rise near a dangerous level, pressure relief valve (26), at 120 PSI, will release and vapor would travel along emergency escape line (28) and into the exhaust pipe near the muffler for a safe disposal of fumes. (Or is the vehicle has a catalytic converter, just ahead of it.) At that same time, a whistle (27) installed in vapor line (28) would sound, thus alerting the operator to the malfunction.

When vapor is being used, it travels through the line (29), high pressure regulator (31). These pressure regulators are mounted in series and drop the pressure to the proper level for the entire carburetor. The lock-off valve (32) holds back all vapor when the ignition switch is off. When the ignition switch is on, lock-off valve (32) is open, allowing low pressure vapor in high volume to go through vapor line (33) to the carburetor.

The carburetor may be of the type used for LP gas operation. But it would be better to use the existing carburetor already mounted on the engine (for use with liquid gasoline), using a dual fuel application such as is used with LP gas, thus allowing operator to switch from using the vapor system to liquid gasoline or vice versa. If engine has remained idle or unused for a long period of time, it may be necessary to use the liquid gasoline system already on the engine until pressure in tank (22) is built up. A switch on control panel allows the operator or driver to change from one system to the other at will. Also, a pressure gauge mounted on the panel can tell the operator or driver when pressure in tank (22) has reached sufficient level for operation - approximately 50 PSI or higher.

SPECIFICATIONS

2. Gasoline Pump: 12 volt or the voltage of the system it is used in. The type used normally in autos.

5. Lock-off Valve: 12 volt. Remains in closed position when ignition switch is off; when ignition switch is on, it remains in open position. It is an added safety feature to prevent seepage of vapor into the into the gasoline tank (1) when engine is not in use. It is the type used for liquid gasoline.

6. Check Valve: A one way valve which allows liquid to be pumped toward the vapor maker, but not permitting vapor to be pushed toward gasoline tank (1) while system is in operation.

8. Vaporizing Tank: Anywhere from 8 to 16 inches in diameter and 14 to 24 inches high, depending on the size of the engine it is used on. The upper chamber (10) occupies the top 1/3 of the vaporizing tank (8) and is strictly for holding liquid gasoline when enough of it has been vaporized to raise pressure sufficiently. The bottom of the upper chamber slopes at approximately 20 or 30 degrees toward the center tube (14) so that liquid gasoline can drain back down completely, even when the vehicle is operating on a hillside or slope. The lower chamber (9) also has a sloping bottom at approximately 20 or 30 degrees toward the center where a cup like pocket, about 2 inches deep and 3 or 4 inches in diameter is located for the tube (14) to protrude about halfway into. This is necessary to keep the lower level of the liquid gasoline below the coil (17) no matter how steep the hill the vehicle is climbing or descending. The vaporizing tank (8) is mounted in an upright position and should be built to withstand internal pressures up to 200 PSI.

11. Valve: A specially made valve which normally remains open to vapor travel both ways between upper chamber (10) and lower chamber (9). It has a standpipe (11a) which reaches to within 1 inch of the top of upper chamber (10). This valve (11) closes to traffic both ways when the pressure in the chambers (9 & 10) reaches 50 PSI. It does not need to be a high volume valve and can be controlled by a bellows type unit which is sensitive to change in pressure.

12. Float: and 13. Inlet Valve: This assembly should be made of material that can withstand high heat and high pressure and still remain in operation.

14. Tube: Is permanently open into the very bottom of the upper chamber (10) and at the other end near bottom of the lower chamber (9) at the lower liquid gasoline level (16) - about half way between the top and bottom of the cup like pocket located in the very bottom of the vaporizing tank (8). This tube is 1/4 inch inside diameter.

15. Upper Liquid Gasoline Level: Should be at least 2 inches above the coil (17). It is controlled by float and valve assembly (12 & 13).

16. Lower Liquid Gasoline Level: Should be at least 2 inches below the coil (17) and is determined by the location of the bottom end of the tube (14).

17. Heater Coil: Is mounted at least 1 inch above bottom of chamber (9) - at least 1 ½ inches cup like pocket of chamber (9). It remains totally submersed in liquid gasoline except when the liquid gasoline has been forced up the tube (14), lowering the liquid gasoline down to level (16) which would be at least 2 inches below the coil. This coil (17) can be 12 volt electric, controlled by a thermostat at 200 degrees. Ore it can be a pipe through which hot exhaust is gases from the engine exhaust manifold. The exhaust is then returned to the exhaust pipe somewhere between the exhaust manifold and the muffler, preferably nearer the muffler, at a point where a slight ventura is built into the exhaust pipe to insure suction, or the flow of exhaust gases through the heater coil (17). It may be necessary to use a thermostat control to cut or even stop flow of exhaust gases through the heater coil (17) when the temperature reaches 200 degrees. PLEASE NOTE: It may also be necessary to use a pressure switch located in tank chamber (9) to shut off all heat if pressure should rise above 90 PSI - regardless of which heat system is used.

18. Check Valve: Is a one way valve similar to valve (6) except that it is a type used for vapor. It is to prevent the vapor from the pressure tank from seeping back through lines (19 & 21), but allows the pump (20) to pump vapor into the tank (22).

20. Vapor Pump: 12 volt electric and can pump hot vapor up to 110 PSI. It runs at continuous operation while ignition switch is on.

22. Pressurized Tank: Is pressurized by the vapor pump and should be strong enough to withstand pressure exceeding 200 PSI. It could be anywhere from 10 inches to 24 inches in diameter and from 17 inches to 36 inches long depending on the size of the engine or the volume of vapor needed.

23. Pressure Relief Valves: Remains closed until pressure in pressurized tank (22) is 90 PSI at which time it opens, allowing the excess pressure or vapor to go through the line (24) and jet (25) into the lower chamber (10) of tank (8).

25. Atomizing Jet: Sucks liquid gasoline in through the bottom of the unit and mixes it with the vapor going through line (24) and jet (25) and forces the mixture out through several small holes.

26. Pressure Relief Valve: Is like valve (23) but it is set for 120 PSI. It is for emergency, in case of any malfunction causing too high pressure in tank (22) and should be mounted on the top of tank (22).

27. Whistle: Can withstand high heat and make a loud, shrill sound when vapor is blown through.

30. High Pressure Regulator: and 31. Low Pressure Regulator: Such as are used in LP gas operations. Both are adjustable and are mounted in series.

32. Lock-off Valve: Similar to, and has the same function as valve (5), except that it is a type used for vapor.

33. Vapor Line: From Regulator (31) to the carburetor should be large enough in diameter to allow high enough volume of low pressure vapor through it to maintain engine speed. Depending on the size of the engine, it should be anywhere from 1 inch to3 inches in diameter.

Parting shot:

I had uncovered this set of plans which I had forgotten about due to a stroke, they are unproven, and have been setting in my files for something like 35 years. However, if this one works, it would be most likely to overcome the modern gasoline configuration. I don't know until it is tried. I no longer have what it takes to test these things. If you want to try it, you would have to do it totally at your own risk. Over the years, I spent many, many weeks' effort on them, but am charging nothing for them. Whatever you do, be very careful! Gasoline vapors are very explosive! Make sure all your insurance is paid up. One last request: Please leave a message here of any reports of your successes or failures.

Gasoline reformulated

In the US and probably elsewhere, gasoline was reformulated to no longer allow Pogue type carbs to work properly.

Phil Ratte explains how:

Catalytic cracking started to be used by oil refineries in the late 1930's. Just in time to defeat Pogue's carburetor and any others that used a vaporization principle. The use of catalytic cracking increased the amount of gasoline that could be produced from a barrel of crude. It also allowed heavy ends to make up a portion of the gasoline. Heavy ends are long chain hydrocarbons that have a high vaporization temperature. In fact, the spontaneous ignition temperature of the light ends is higher than this vaporization temperature so if you heat the gasoline high enough to vaporize the heavy ends you explode the light ends.

A friend of mine used to go up to Winnepeg, Canada in the 1980's to visit Pogue who was living in a Nursing Home at the time. One of the stories that Pogue told him was about the Battle of El Alamein that was the turning point of WW II. Previous to this battle, Rommel's Tank Corps would chase the British tanks till they ran out of gas. Rommel's tanks would then retire and allow the artillery to destroy the British tanks. They could do this because they had more efficient engines with a longer range.

Pogue had been hired to design a combustion system for our tanks that gave them a greater range than Rommel's tanks. At the battle of El Alamein, our tanks ran Rommel's tanks out of gas and our artillery picked them off like ducks in a shooting gallery. Whenever one of our tanks with Pogue's combustion system was disabled or destroyed, there was a crew who would dismantle and remove the combustion system in these tanks that were sealed in a black steel box.

There is a website and a CD that have 604 carburetor patents that have been assigned to various companies and never developed. There were 53 inventors who wouldn't sell out. Each of them had fatal "accidents" two to three weeks after refusing to sell their patent(s). I knew four of these inventors personally. The website is http://www.fuelvapors.com/.

Phil Ratte is a retired mechanical engineer, who graduated from the University of Minnesota with a BME (Bachelor of Mechanical Engineering) degree in 1961. A few years later he got his license as a Registered Professional Engineer in the State of Minnesota and later in the State of Wisconsin.

In 1978, Phil ran for the U.S. Senate on a platform of new energy related ideas that included ethanol blended fuels.

From 1979 to the present, Mr. Ratte has tested over 90 devices and additives that promised to save fuel and reduce pollution.

In the 1980's, Phil designed 4 buildings using SolarCrete. Three commercial buildings and one home which use 75 to 80% less energy than similar buildings of other designs. These buildings should last over 500 years. They are earthquake proof and will withstand 300 mph

winds.

From 1981 to 1989, Phil worked with a wealthy inventor, Herb Hansen, to develop two prototypes vehicles that ran on 1/3 ethanol and 2/3 water. Herb died of a major stroke at a very convenient time for the Oil Cartel. Two months after Herb died the U.S. Secret Service entered Phil's home with a warrant and copied his files on their ethanol project. When he tried to find out what the Probable Cause was to issue the warrant, he found that the Federal Judge had sealed the file. Phil has known 4 men including Herb who died after refusing big money for their very promising energy saving devices.

53 inventors with revolutionary energy saving inventions have met untimely "accidental" deaths just after refusing large sums of money for their patents. Other inventors have received millions of dollars for their patents that were then left undeveloped. Phil says he has a CD that has 920 energy saving patents in it that were assigned (sold) to various automobile, oil, and other companies and then buried.

In the 1990's, Phil was hired to do testing for two companies that were selling magnetic fuel saving devices. He appeared as an expert witness in a criminal trial in Missouri. His success there caused the 29 states that were prosecuting the second magnet company to quietly drop their cases. It also caused the Minnesota Attorney General to try to attack Phil's Minnesota Professional Engineering license. That Attorney General was Hubert H. Humphrey III who Phil helped Jesse Ventura defeat for Governor in 1998.

It is very strange, says Phil, that after 1994 magnets could no longer improve fuel efficiency. Apparently the computer chips in cars after that time were programmed to defeat any device like the magnets that provided more complete burning of the fuel and potential fuel savings. (Any underground programmers out there who can re-program these chips to take advantage of novel fuels?)

Phil's web page: ENERGY INDEPENDENCE IN SIX YEARS

See also:

McBurney Cracks the Code for Super-Carburetors

Inventor J. Bruce McBurney says the key to super carburetors is the catalytic cracking of the larger gasoline molecules into the dynamic combusting single-carbon molecules of methane and methanol, in the presence of heat, a catalyst, and water vapor.

The 50% MPG Gain That Detroit Won't Touch

(Washington Post - you may need to register to see the article)

Vaporized fuel, when properly mixed with air, burns more efficiently, saves fuel and emits fewer tailpipe pollutants than traditional fuel-air mixtures in which gasoline is sprayed into a combustion chamber in tiny droplets and then mixed with air before burning. All car companies know this. Most have sought to increase combustion efficiency by swirling gasoline in intake valves before mixing it with air and by using computers to more precisely open and close engine intake and exhaust valves to better meter fuel-air mixtures. The manufacturers' rapid-swirl, electronically controlled variable-valve lift technology has brought about substantial increases in fuel efficiency--but nothing near the reported 40 percent to 60 percent improvements in efficiency touted by inventors of the pre-heating, fuel vaporizing equipment.

Here is a guy who seems to have mastered the vapor trick.

Video on YouTube: White Gasoline Vapor could slow Global Warming, save money, & have more Power than ever.

Update January 2011:

A reader, Gary T. Kirkland, asked if he could put up a photo. He says he obtains a flame similar as that from butane gas, when burning a 100:1 mix of air and vaporized gasoline. Here is his message, for those who may be interested...

I would like an answer to a question. Please look at the attached Photo of my Gasoline Vaporizer. With the aid of a low pressure Air Compressor, Vaporized Gasoline at 100 parts of Air to 1 part of Fuel, intended to power an Engine, is instead safely ignited to prove that it actually works. Notice the colors of the flame. It goes from Blue to Yellow to Orange. This is the very same flame color pattern of a bic butane lighter. This is proof that there is really no difference between Butane and Gasoline.

With Vaporized Gasoline, even the largest SUV could easily get 50 + MPG, and emit a fraction of the Emissions of an EPA-OBD II mandated fuel system, which operates at 14.7 parts of Air to 1 part of Fuel. Also, with Vaporized Gasoline, there's an increase in power, as well as much longer engine life. And the resulting Flame has a much lower combustion temperature than Natural Gas, or Propane, both of which burn Blue. Hydrogen burns even hotter. The problem with such a high combustion temperature is that an Engine has to be modified to withstand it, which is very expensive. Again, not so with safely Vaporized Gasoline.In the past, Vaporizers relied on engine heat to function. With the additives in today's Fuel, that's all but impossible. My unit uses low pressure Air to do it's thing. But there is another problem. All Gasoline powered vehicles from 1996 to the present are required to pass the EPA-OBD II vehicle emissions inspection. All such vehicles have on board oxygen [O2] exhaust sensors. These O2 sensors are set up to detect a level of polluting Exhaust Emissions that would indicate that Fuel is being metered into the engine at 14.7 parts of air to 1 part of Fuel. This is detected by the level of polluting Exhaust Emissions registered when a vehicle is connected to an OBD II Emissions Analyzer for it's annual Emissions Inspection.

Anything below 14.7 / 1 would result in an excess level of polluting Exhaust Emissions being generated. This will result in a failed Emissions Inspection, as well it should. But, with a vaporized fuel mixture of 100 parts of Air to 1 part of Fuel, the result will be far less polluting Exhaust Emissions. O2 sensors are incapable of registering anything far below the established resulting emissions of an air/fuel Ratio of the 14.7/1 level. An O2 sensor failure code will result if such a vehicle is connected to an OBD II emissions inspection analyzer.

O2 sensor exemptions are granted for vehicles that have been legally converted to operate on Natural Gas, Propane, or Hydrogen, and are registered as such. But no such exemption exists for Vaporized Gasoline. Thus, it is entirely possible for any vehicle from 1996 to the present to fail an Emissions Inspection for not emitting enough polluting Exhaust Emissions! Also, since the vast majority of Vehicle Manufacturers wish to sell their Vehicles in the U.S.A., they are made to comply with this EPA-OBD II Law. Thus, this amounts to a World-Wide Issue.

I'm convinced that alternative use of conventional Energy, at least in the short term is the way to go. But the Big Oil Corporations, with Big Government in their pockets, are going to fight this every way they can!

For even more insight, do a search on [the late] Tom Ogle. Then, go to http://energy21.freeservers.com/bookrep.html. Scroll on down the Page and check out the last few Paragraphs just before the Update. Until this insane EPA-OBD II Law that only benefits Big Oil is changed, the only way to make vehicles more "efficient" will be to make them smaller and lighter. I have contacted, and joined the new Administration's site, www.change.org and they're too busy to be bothered with it. Likewise www.friendsoftheearth.com, www.michaelmoore.com www.algore.org and many other Environmental Organizations as well.

Not one of them, nor any Politician can or will honestly answer my question: "Why is it illegal for any vehicle from 1996 to the present to emit too little polluting Exhaust Emissions "?

I'm not trying to sell anything. Everyone else that's tried to do so has been effectively stopped one way or another. But I must ask, if you truly care about the Environment, can you please answer my question? No one else seems to be able to do so.

Thanks ! Gary.

Eric comments (by email):

these patents are long since expired - if they really work, anyone could reproduce them. About 20 countries in the world can make cars, I see no reason none of them would want to totally take over the trillion dollar car marketplace and have a balanced budge by not having to pay for oil

My reply:

yes it seems incredible, yet only tinkerers are doing it. I know of a few who are using such a system - one sent over a video - but there seems zero interest by the car companies. As long as what they have works well (for them), who wants to rock the boat?

John K sends a link to this announcement:

AUTOMOTIVE X PRIZE ANNOUNCES DRAFT GUIDELINES FOR COMPETITION

Innovators Invited to Help Solve One of Our World’s Grand Challenges

Santa Monica, Calif. (April 2, 2007) - The X PRIZE Foundation, the organization behind the $10 million Ansari X PRIZE that successfully challenged teams to build private spacecraft to open up the space frontier, is taking a step toward launching an Automotive X PRIZE (AXP) that will inspire super-efficient vehicles that exceed 100 miles per gallon or its equivalent.

In draft guidelines to be released at the New York Auto Show, the AXP outlines an independent competition that will result in clean, efficient vehicles that help break our addiction to oil and stem the effects of climate change. The AXP also invites interested teams - major auto companies and innovators alike - to execute letters of intent to participate as the AXP moves toward an official launch later this year.

"We invite the world's best and brightest minds to look at this independent, high-profile competition as a way to make a difference for generations to come," said Mark Goodstein, executive director, Automotive X PRIZE. "In the spirit of grand competitions throughout history - including Lindbergh's historic flight across the Atlantic 80 years ago - we expect that the Automotive X PRIZE will bring about change and innovation for the benefit of everybody. This competition will help level the playing field and capture entrepreneurial, scientific and technical energy to bring about viable cars that consumers want to buy."

The draft guidelines outline a challenging multi-year competition with a multi-million-dollar cash purse. Teams first are required to meet arduous standards proving they are capable of designing and building production-capable, super-efficient vehicles. The vehicles then will compete in a series of rigorous stage races that test the vehicles under real-world driving requirements and conditions. Vehicles will compete in two different categories - Mainstream (4+ passengers, 4+ wheels) and Alternative (2+ passengers, no requirement on number of wheels). Winning vehicles must exceed 100 miles per gallon or its equivalent, while also meeting rigorous emission requirements...

A reader who does not like to be named says vaporization works but is not well compatible with our piston-type internal combustion engines:

Hi,

Thanks for your message. Just by way of comment, here are some details:

Several atomization systems have been proposed over the years. The problem is that they are not compatible with piston engines. Search the SAE database for details (generally, no more than 40% of the fuel must be atomized).

Basically, piston needs the maximum pressure 20 to 30 degrees past the top dead center,

so that the combustion must be somewhat delayed for optimal operation. Small droplets help providing this delay. Atomization make the combustion too fast and too hot (near stochiometric), and rapidly damages the piston exhaust valves.

Modern computer injection systems go exactly in the opposite direction, by injecting all droplets with almost no atomization. Because the volume of fuel vapor occupies 600 times the volume of liquid fuel, pre-vaporization of the fuel removes space for air intake, and reduces engine power (which is sometimes confusing, because it could lead to increased miles/gal, but at lower power level).

In modern piston engines droplets are such that combustion occurs at the right time and almost completely. There would be no significant energy efficiency gain by going atomized.

Atomization is however suitable for detonation engines like the Quasiturbine. In that kind of engine, combustion needs to be very fast and volumetric.

Not intended as criticsm, it's just plain info.

Paul Werbos says by email:

I don't believe it.

Great breakthroughs can be had in car design (see www.werbos.com/energy.htm), but not by ignoring

the basic principles that govern the numbers.

You can't get four times the mpg, for the same size and weight of vehicle and the same fuel, without multiplying the engine efficiency by four. That's hard to do when it's about 25% or more already (at nominal loading) and it's a heat engine limited by Carnot's Laws. If the guy makes crazy or just misleading claims on one central thing... it casts doubt on the rest.

The pattern of fuel injection doesn't solve the off-nominal energy loss problems or braking loss or the rest.

Besides, the challenge for now is to get off of gasoline in any case.

Best of luck to us all,

Paul

All the motor vehicle manufacturers are in full knowledge that gasoline does not burn, but only the vapor burns, and they know how to do it. However, ever since the original Henry Ford died, every single auto manufacturer is too scared spitless to buck the system established by the gasoline companies. Every auto maker is firmly in the oil industry's pocket, and woe to any who tries to creep out! When Ford Motor Company first came out with the Ford Falcon, it got 32 MPG, but right the next year, Falcon only got 25 MPG. Soon after that, when SKI Corp. (Frantz Oil Cleaner Co.) wanted to start selling a carburetor that was guaranteed to get at least 45 MPG on any American made auto, their lawyer discovered a law that was now on the books, making it against Federal law to manufacture, sell, or install a carburetor that got over 25 MPG. So they had to scrap the whole thing! In later years, due to popular public pressure, the EPA made the FEDS bend that rule, and we saw higher mileage American made autos on the market. It was like the higher mileage autos were brought out grudgingly though. You'll notice that they keep trying to slip the gas mileage back down every chance they get. The scenario we now have is the Feds, the gas companies on one hand, and the EPA under pressure of the people on the other hand, with the auto industry in the middle, trying to appease both sides!

You'll never have a big company come out with an ultimate mileage carburetor. It will have to be done by private individuals, and only for themselves. If enough of us do it, we may eventually turn the tide a bit.

p.s.

I only drew the plans. Because I am disabled, others made the working models, using my plans, and were amazed at the results. However, the gasoline in the US and Canada has now been specifically formulated to make sure these types of carburetors no longer work. I don't know if gasoline in Europe has the same additives.

Cant subscribe. get rid of feedblitz..here is what I sent them. Type your request here: NOBODY IN MY HOUSE CAN properly discern the difference between figure 1 and capital I in the text.. also the light pastel shade makes it worse to read.. We are not disabled or blind.. forgiver me for suspecting you don't want me to subscribe.. I spent 5 minutes with a magnefying glass with the first attempt which failed, and was sent another different code which was even worse.. I gave up..

Sorry about that mess with Feedblitz. It will take a while to sort out.

Anyway, I have added your email to my personal notification list so you'll get updated when new articles come out.

Anyone else having trouble subscribing - just email me and I will add you to manual notification of new articles.

Sepp

Catalytic cracking started to be used by oil refineries in the late 1930's. Just in time to defeat Pogue's carburetor and any others that used a vaporization principle. The use of catalytic cracking increased the amount of gasoline that could be produced from a barrel of crude. It also allowed heavy ends to make up a portion of the gasoline. Heavy ends are long chain hydrocarbons that have a high vaporization temperature. In fact, the spontaneous ignition temperature of the light ends is higher than this vaporization temperature so if you heat the gasoline high enough to vaporize the heavy ends you explode the light ends.

A friend of mine used to go up to Winnepeg, Canada in the 1980's to visit Pogue who was living in a Nursing Home at the time. One of the stories that Pogue told him was about the Battle of El Alamein that was the turning point of WW II. Previous to this battle, Rommel's Tank Corps would chase the British tanks till they ran out of gas. Rommel's tanks would then retire and allow the artillery to destroy the British tanks. They could do this because they had more efficient engines with a longer range.

Pogue had been hired to design a combustion system for our tanks that gave them a greater range than Rommel's tanks. At the battle of El Alamein, our tanks ran Rommel's tanks out of gas and our artillery picked them off like ducks in a shooting gallery. Whenever one of our tanks with Pogue's combustion system was disabled or destroyed, there was a crew who would dismantle and remove the combustion system in these tanks that were sealed in a black steel box.

There is a website and a CD that have 604 carburetor patents that have been assigned to various companies and never developed. There were 53 inventors who wouldn't sell out. Each of them had fatal "accidents" two to three weeks after refusing to sell their patent(s). I knew four of these inventors personally. The website is http://www.fuelvapors.com/.

My name is Phil Ratte. I am a retired Mechanical Engineer (BME 1961 U of MN) who practiced as a Professional Engineer for 27 years in Minnesota. I ran for the U.S. Senate last year on one issue, Energy Independence. Amy Klobuchar was a fast learner and defeated NEOpubliCON Congressman Mark Kennedy by over 20% using this issue. In 1986, I ran for Governor of Minnesota with a single issue campaign, Ethanol Fuel from Minnnesota Corn. We are now the number one state per capita producer of ethanol. Minnesota has more E85 (85% ethanol) gas stations than all the other states combined.

Answer to Paul: Liquid gasoline, whether it is injected, atomized into droplets, are in one class. Gasoline vapor is in a class by itself, and the calculations are altogether different.

In 1985 I lived in Binghamton,NY. I offered jobs to three of my friends from Madison,WI. They arrived one day in a 3/4 ton Chevy pickup with 33 inch tires. I said that must have killed them money wise for gas. They said they spent $9 for gas. I was amazed and asked how so. They opened the hood and there was a black box where the carburetor should have been.They told me they got 210 miles per gallon. I asked did they invent the device and they said no. It was their version of the Pogue plans from the public library.They then drew the plans for me in pencil. It was very simple and had no moving parts except for the choke and throttle valve.I was told if it wasn't built right, it would turn into a bomb.I was told to put my face down to the exhaust and smell. I said I couldn't smell anything. They said that was because 99% of the fuel was being burned.This was their 3rd prototype. The first ran a lawnmower for a week nonstop on a pint of gas. The second got just over 100 mpg on a Ford LTD stationwagon. They were very paranoid about having these.I have lost touch with them over the years. My own truck, Chevy Blazer 1986 350 ci. gets 22 mpg by the use of water vapor.1 cubic inch of water vapor expands 5 times more than 1 cubic inch of gas vapor. This was shown to me by an airplane mechanic who said the B52 bombers used this in world war 2.

Very interesting info that connects many dots -- Have you checked the fuel economy work of the folks at www.brightgreen.us and Fuel economy tips - lots of info and suggestions and some small devices to enable the individual to "double " their current milage

Involves "preheating fuel" -- certain additives that apperently counter the effects of the oil co. additives --- requires ATTENTION TO DETAILS by the average home mechanic --- results verifible by dashboard SCANGAUGE --- one of the essentials is to get the engine running as smooth as possible peace ken

Question for Phil Ratte : So they changed the formula back in the 30s? Might they have further defined the formula since then, or added more restrictive additives? The reason I asked is because my carburetors worked in the 70s and 80s, but they don't work with US gasoline today. Frank

Interesting,

Yes, we have all heard and read about the super carbs over the years, and no doubt, the oil companies can modify the gas to suit their needs and desires, so nothing new here either.

With so many additives available to alter the fuel burn, it would be near impossible to introduce a product which would enhance fuel performance these days. Just look at BTF was the most recent fiasco big oil pushed down our throats in the name of reduced emmissions, and it turned out to be worse for the environment.

I have been testing different fuel additives for years, and everytime one looks promising, a new additive is introduced, so I can relate to the cracking change in the 30's, nothing new here, big oil will do everything possible to protect their billions in profits every year.

www.Gas-Scam.com

It is interesting to note that the auto industry does not want high mileage. Back in the early 70's during the so called "oil crisis" (not!) that is when they produced vehicles with much less mileage potential. This was done mainly to offset the conservation measures taken by the consumer, which perhaps both the auto and oil industry under estimated.

One thing that none of the comments touched on is the conspiracy of a handful of men known as the Illuminati, also known as the Banksters. If you think that the free world is run by their sovereign governments, you are sadly mistaken. You all know the golden rule of the arts and science; whoever owns the gold makes the rules! Henry Ford correctly accused the Banksters of starting WWI. What was the purpose? To rid Europe of it crowned heads. WWII was designed to finish what WWI did not. This is just the tip of the iceberg of what is really going on in the world. Both the auto industry and the oil industry are in bed with each other, simply because they are run by Masons that are the pawns of the Illuminate.

All your major corporations are headed by Masons. Big Pharma came from the medical experiments done on Jews during WWII. During the Nuremburg Trials, key people that did those experiments were exempt from prosecution. The Illuminati also controlled those trials.

There are hundreds if not thousands of murders, accidents, etc that were perpetrated by the Illuminati. More recently over 200 microbiologists lost their lives since 9/11. This type of thing is unprecedented and the odds of such a thing happening are billions to one! Do you really believe the World Trade Center collapsed because of the fire(s)? NOT! Everything is by design; anything political is well planned. Our occupation of Iraq serves the Illuminati and their agenda. G.W. Bush is just like his daddy; a New World Order man. Ever since FDR (who was ordered by the Illuminati to ship gold to Germany to rebuild their war machine), the United States has been carefully controlled through the political system, mostly through what Eisenhower referred to as the Military Industrial Complex, which is still evidently alive and well.

It is also interesting to note that the Bush administration is acting with impunity in regards to the erosion of our “Rights” per Patriot Acts I and II. Not to mention the cooperation of the phone companies that are allowing illegal wiretaps. Well, what do you expect from companies that are run by Masons? Breaking a clear Constitutional Law by allowing illegals to overrun the country, Re: Article I, section 8, clause 15.

The Federal Reserve System is the largest fraud ever to be perpetrated on mankind. Which by the way will soon collapse under its own weight and that currency will be replaced by the Amero slated for 2010. What is going to happen after that will make Black Tuesday look like a Sunday picnic? My suggestion: get out of debt ASAP. Sell your houses and get a cheap apartment. Take the left over money and purchase “hard money” like silver and gold and not on paper. Watch the silver and gold markets, even if they dip a little; it will generally take a steady and sure climb and perhaps peak around 2012. At about that same time the middle class will cease to exist. The only survivors of the coming economic upheaval are going to be the cash rich and the subsidized poor. Do not buy into anything the government, Big Pharma and the banks want to force upon you. We must resign ourselves to taking responsibility for our own lives as is the Constitution prescribes.

Very interesting, M. R. Rowley. All true as far as it goes – it is actually only the tip of the iceberg. I would disagree, however, with using gold and silver as a hedge. When the world goes completely off the gold standard, precious metals won't be worth gravel.

I gave up long ago to trying to change the world with my inventions, including carburetors. If we do anything, it will be on an individual basis, and for ourselves.

Gerald Rowley comments (by email):

I was able to build my own fuel vaporizer and patent it.

I am able to go 43 mpg. Normally i could go 30-31 mpg.

Do a Google search for Vapster and see.

Thanks, GR

- - -

addition from a later message:

I am currently installing the device on several vehicles, Ford Explorer, BMW, Dodge Caravan, etc.

Also, I am going for a new patent with the upgraded version of Vapster.

Very good, Gerald. 30 or 40 percent increase is savings indeed. However, if you should come up with, and try to market, a carb that gets much more than that, you better have a real good life insurance policy.

Earlier an email said that injection brings tiny droplets into engines, 20 to 30 degrees after top was the best for bringing power to piston-engines and that there was no place (enough) for air to make vaporized fuel having power and good mileage. Well then, a solution (even for the modern car) in raw terms: disable your ecu (this will disable all fuel injection and all sensors (a prison for thinkerers), put in your vaporizer, and set the spark timing at 20 degrees AFTER top. For increased power, add some metal tips in your airchannel with high voltage which will create ozone (o3) and you can add a vortex ring in your airchannel as well which increases the air-intake.

disabling your ecu will bring down your electronic ignition as well... so maybe you have to add another one, or figure out how to use your own without the rest influencing it.

Re:"April 15, 2007 04:36 PM | Posted by: Ron"

Good note.Just one little "glitch": there were no B52's in WW2. The B52, being a turbojet bomber, didn't come along until about 1956 or so. They may have been re-engined to turboFAN level over the years - who knows.

Hal Ade

Gatineau, QC

In the early 1960s, I moved to Ontario, Canada to be near my girlfriend. While there, an acquaintance told me how he and his brothers were messing around with an old auto their folks had. They disconnected the gasoline line coming from the gas tank and ran the engine until the carburetor was completely dry of any gasoline. Then they draped a garden hose into the top of the carburetor and strung it across the yard to an old gas tank that had a little gas in the bottom. Then they cranked the starter until the engine fired up. They ran the engine for quite a while with just the vapors from the top of the old tank. Boys, being boys, they revved the engine a bunch of times until it backfired. They heard a sharp whistle going down the hose, and ducked. When the whistle stopped, they sat up again, just in time for the big explosion, and shrapnel all over the place! There was nothing left of the old tank! And apparently they survived to tell me about it later

I know a fella that has discovered non-detonation nano-diamond powder . This material has molecules several times smaller than the diamond powder produce by detonation and it not contaminated by the TNT residue . He first applied his material to the wheel bearings of a mack truck . The fuel economy went from 5 MPG to 8 MPG just from the reduced friction . He then added the material to the oil , diesel fuel and transmission . It's also proven to correct fuel injector gum ups . His barber no longer has to oil his clippers .

I would like to hear more about and/or get some of this non-detonation nano-diamond powder...

James Hanlon, Please send more info on the diamond powder. If it works like that I may have people that can help take it to market.

To anyone who is interested, there is someone selling a product called "NanoLube" which fits the description given by James Hanlon...

I did a study on the Pogue vapor carb and other devices around 1990 and came to the conclusion that the reformulated gasoline was not going to work as a high mileage fuel source. Recently I have been studying Hydrogen (water) technologies for running our Motor Vehicles, I have found that a few inventors in the past 10 years have met with un-timely deaths as well after refusing to sell out to Big Oil! Do a Google on Stan Meyers, this will lead you to a very productive study about how to run your car on Water (Hydrogen converted onboard). I do think this is the future and truly deserves our attention and effort instead of antiquated fuel systems that are controlled and manipulated by a big cartel.

I'm not an engineer or technician, but the claims that vaporized gasoline will not work in a piston engine seem to me to be quite false. After all, we have LNG and propane powered busses, police cars, etc all which were converted directly from gas powered fuel injected engines. Its all about the computer, the sensors, and the programming.

If you really want to dabble in this you should get a motorcycle engine which does not have any of the computer equipment, install a variable cam gear where you can adjust the cam timing and measure your results. this can all be done on the bench in your garage (with vent pipe to vent the exhaust). prove your theories there and then take them up a step to an old-pre 70's car. The point is, trying to achieve any of this on a modern day car with all the variables in place makes it extremely difficult to tune the carb apparatus that you are trying to build. Perfect your ideas in a controllable environment then move into the more modern engines. This of course is assuming your goal is to build a bolt on apparatus.

And lastly, you should do it in plain view of others. Meaning you build it, patent it, then open source it so every other tinkerer can help develop it. Once patented, it can't be "stolen" and once open sourced, it can't be bullied by big oil. Of course no idea is perfect and even these I've posted have their own flaws.

I am reporting herein a question and answer that has passed my way. I will not reveal the names of the people involved. If they wish to reveal themselves, that is up to them. ----

I am a Alternative Energy researcher and I would like to know when that Federal law came about 25 MPG for mainsream auto's. Could you direct me to that Law? I am presently organizing XXXXXX XXXXXX XXXXX to go up against the corporate oil and auto industry. Any info you could provide would be helpful on that post that Frank gave in this site. ........................

P.S. I find it absolutely outrageous that the public does not know about this law...How can it be legal to even pass a law like this without the public knowledge?......The mainstream media has a blackout on this and suppressed technology..........

******************************************8

Dear XXXXX,

I have been very sick for several months, so I hadn't been checking things like I should have. I will tell you what I can right now from memory, but if you can't find out from that information, let me know, and when I am feeling better, I'll look up more detail for you.

In the 1960s, or there abouts, I was selling Frantz Oil Filters, and at that time, Skipper K. Yee owned the company. The Frantz was sold on a multi-level basis, and was going great guns. We were introducing new automotive products to go along with the Oil Filter line, and there was a great anticipation for a carburetor that was guaranteed to get at least 60 MPG on any American made auto. Just before the introduction date, the whole carburetor thing came to a sudden halt! That was when we were told that there was a law that any American made motor vehicle were not allowed to get over 25 mpg by Federal law!

I don't really know any more about it than that, but I remember that when the Ford Falcon first came out, that first year, they got 32 MPG. Right the next year, the MPG was jerked down to 25 MPG, and after that, all American made Autos stayed below that line, until the EPA entered the picture in more recent years, (a classic case of one government agency over another) that MPG was forced upward.

The Auto Industry is firmly in the Oil Industry's pocket, as you can see by their recent ads about the "impossible" MPG rules that are now being handed down. Well, my heart bleeds peanut butter for them! Those guys know exactly how to do it, but will play politics as long as they can. Same as it has been, it's BIG money games. If EPA wins this one, it will be much better for us this time

Frank

A comment and question from Lilian Cipciriuc by email ... and my answer:

On 16/giu/07, at 09:47, Lilian Cipciriuc wrote:

Dear Josef

I found your blog page http://blog.hasslberger.com/ when searching for Pogue carburetter. My interest brought me to find the respective web page. In my turn I try to find more info about increasing the MPG for my Mercedes 210 MiniBus, which is a diesel engine of 3 litres volume.

You mentioned Frank, a canadian chap, and I think I know who you are talking about - Alan Francoer, may be. If I am wrong doesn't matter. I have found some info and as well few blueprints on a page whose address i've cleaned from my browser history, but it can be found, if needed.

So, my topic sounds like this - is there any way to use vaporizing for diesel engines? I am not an motor engineer, if the questions sounds to you weird, I just want to see if there is any way to make my diesel be less consuming of diesel and still powerfull.

All respect

Lilian Cipciriuc

p.s. I stay usually on www.skif.biz - a russian site for alternative research on energy and saving energy

My answer to Lilian:

I have not heard of any possibility for vaporizing diesel oil - the Pogue system seems to be specific for more volatile fuels such as gasoline or ethanol.

To save with diesel engines, some people use vegetable oil that in most countries is cheaper than the diesel they buy at the pump. This can be used in diesel motors but I am not sure what modifications - if any - would be necessary.

Another technology that can be used with diesels is magnetic fuel conditioning, where you have a magnet somewhere on the fuel line that is supposed to make the diesel burn better.

Or you could try one of the additives that decrease friction in the motor by making the oil more effective, or by actually creating a slippery film on metal parts in contact with the oil.

As a long term handling, if you have to stay with a diesel engine, newer ones get more and more efficient. Turbocharged diesels are starting to be better than gasoline engines.

To Lilian Cipciriuc,

The web site you mentioned,

www.skif.biz , is all in Russian. Would there be an English version of the site?

Frank, E.

A comment received by email:

I read your article about high mileage carburetors. Although your story has more detail my story is eerily similar. Some time between 1975 and 1980, i read an article about a guy who was working on his lawnmower when the carburetor fell half way off, but it continued to run. He put a fan on it and it ran for 90 hours.

To make a long story short he adapted a similar setup to his full size LTD. Although it took him 3 miles to get up to speed it did average 100 mpg. My memory is a little fuzzy after all these years but the basics of the story are correct. I worked for a transit company between 1975 and 1980 and I had to bring the article to work to show my friend because he didn't, believe me.

Trailer Life ( a well respected magazine) ran a mileage article with this guys setup and one other car with all the latest mileage gismos (like magnets on the fuel line). Anyway each car was carfully inspected and given 2 gallons of gas. The lawnmower guy went 100 out and 100 miles back with a little left over.

I watched that magazine carefully for months and I saw not another word. No follow up articles no letters to the editor, no nothing. It's like he the guy fell off the face of the earth. Anyway if you want to research it, start in Jan. 1980 work backwards. The article will be much closer to 1980 than it will be to 1975. His setup was running on fumes or vapors.

Bob

There are several web pages that translate Russian to English

http://babelfish.yahoo.com/

http://www.freetranslation.com/

are a couple of them.

For example, go to the babelfish site, put in the URL and specify the languages to translate from/to.

In one form or another everything is just a boiler that uses gas as a gas in the way it was originally designed do be used.

Old guys I know have been boiling there fuel for many years (years and years. The newness of this is just because your all the next generation that skipped over the info and are finding it all

again. massive fuel economy is logical and reasonable.

Its corporate marketting subterfuge that keeps the billions of people engineered into consuming no less than

3 times the world petrolium

output. The entire world runs on oil and they are consuming at least 3 times the required rate.

This means that over the last 100 years 2/3 the entire world output of oil and petrolium distilates as well as all the pollution that goes alone with all of that is engineered as a pure profit mechanism.

Reduce the entire world output to 1/3 and you have the maximum

usage however the demand accumulated for the past 100 years.....

The math and all the

schematics of all the worlds automobiles show this clearly and you dont have to look deep to find these referances.

the world consumers are blindly accepting what they are given because they are simple minded

compulsive followers who despirately need some form of marketable leadership. Oil and transpertation is that limitting leadership.

I have been looking into the pogue carberator system of late. I remembered a news print article from the early seventies I saved and dug it out of the pile of boxes. And interesting thing about the new fuels and additives. A gentleman in Montana designed a little device that you plug into the fuel line under the hood. It cleans all the "garbage" out of the fuel so that it enters the carberator/injection system as pure fuel. Without the Pogue systm, he reported 35mpg with a ford v-10. Have you heard about this? I am digging for more intell. Thanks

Since there seems to be a problem with piston engines could the wankel rotary engine be used instead?

TANJ,

a Wankel rotary engine may be a possibility, but perhaps the Quasiturbine described on PESWiki would be better. It can withstand and utilize the rapid expansion of a vaporized fuel, according to its inventor.

The Wankle Rotary Engine has the major problem of way too much friction. My experience is that those engines wear out big time.

A much better rotary engine design would be the Rotary V Engine. There were articles about this engine in the following magazine.

Popular Science, August 1974 (5 pages 62-64 & 117)

Popular Science, February 1976 (2 pages)

Mechanix Illustrated, January 1977 (pages 50 & 52

Sports Aviation, February 1986 (page 14-18)

Here are a few web sites to look up.

http://www.freepatentsonline.com/5601055.html

http://www.freepatentsonline.com/4022168.html

http://www.saintjohn.nbcc.nb.ca/heritage/bricklin/Rotary.htm

Or Google the net for “rotary V engine”

Frank

If I had what it takes to set up a auto manufacturing plant, and could do it "right", I would use the Rotary V Engine, and completely vaporize the gasoline before it reaches the combustion chamber.

Besides the funding,it would take 1. an enormous army to guard against Saboteurs, 2. a staff that wouldn't be afraid to stick their necks out, 3. and guts -- lots of guts!

Others have tried and failed, because that lacked one or more of that stuff.

Frank

This is the kind of stuff that adds the 'nuts' to 'conspiracy'.

Car companies clearly strive to lower fuel use while providing acceptable power. To say they are all limiting their own profitability simply to protect a completely different industry (oil) is absurd.

The oil industry would be fine anyway. More efficient engines would just result in more powerful cars that still used a lot of gas. Do you think the USA likes being dependent on foreign oil?

I am not one of those that dismisses conspiracies simply because they are conspiracies, but this one is just silly.

Dear XOC,

There are overwhelming historical and present day evidences that you may be ignoring or are otherwise ignorant of. Or you may have a vested interest in turning a deaf ear to the truth.

Frank

i used to wrk for a rebuilding co. when i was young and i used to burn the stators and rotors from starters and alternators to get the copper out...any way the fire had been out for a while and i threw a large coffee can of gas into the burn barrel, well it didn't explode as i was expecting, but it did produce quite a cloud of steam like vapours upon contact...well i had a book of matches in hand...i was young remember! lol, and as i struck the match it instantly ignited the cloud around me!! costing me a few eyebrows, lol thinking back on that...i wonder, if you ran heated tubes under the carb, electric or exhaust...changing only the jetting, would the fuel passing through the heated tubes produce a simalar result, using the engines own vacum to pull the vapours into the cumbustion chambers?...maybe a turbo in that formula would make it an interesting little project, for those of us that like to leave a little rubber at the occasional street light!! lol

Another email by Gerald Rowley ...

I would like to thank you for putting up info on my patent on your web site. I am in the process of a second patent which is pending for upgrades to the original patent. Presently, I am seeking fleet vehicles in the S.E. Florida area to conduct beta testing. I would like to install the devices for no charge in return for 50% of the price of the fuel saved. So if a company uses $10,000 of fuel a month and I can save that company $3,000 a month that would be a return to me of $1,500 per month. Currently, we would like fleets of Fords and GM's. Gerald Rowley, Save America.

Gasoline does not burn. Only gasoline vapor burns. If it is cold enough that the gasoline is not vaporizing, you can put a lighted match down to the gasoline, and even if you immerse the lighted match into the gasoline, it will extinguish the match. Now if some of the gasoline vaporizes before the match is immersed, the vapor will burn and the heat of the fire will vaporize more gasoline. Depending on how fast the gasoline vaporizes, determines if the flames will be mild or if there is an explosion.

The gasoline additives that are put into today's gasoline are specifically formulated to control the rate of evaporization to make it difficult, if not impossable to completely vaporize the gasoline until after the combustion in an engine and by the catalytic converter.

If one could overcome the effects of the additives, and vaporize all the gasoline before combustion, the catalytic converter would have nothing to do. But then you could get optimum gas mileage, and the "poor" gasoline companies wouldn't sell near as much gasoline, poor things.

If anyone comes up with a way to safely, and completely vaporize the gasoline before the combustion takes place, he could do his fellow man a great service. However, to be effective, he would have to tell as many people as possible how to do it, because if the inventor tried to cash in on the invention, the gasoline powers that be would snuff him out, and right now.

If instead, the inventor would tell as many people as possible, the gasoline powers that be would have way too many people to snuff out, and the movement could then move ahead. The inventor would not get riches for himself, but he would have the satisfaction of helping his fellow man get out of the clutches of those gasoline powers that be, and help the planet reduce the polution caused by the unnecessary over consumption of gasoline.

So you think corn ethanol is a winning alternative to oil? You may want to rethink that idea. According to an article in the February 2008 issue of Popular Mechanics on page 54, it takes 1.3 gallons of oil to produce one gallon of ethanol, when you factor in all the costs including the hidden costs of production. Those costs include production of farm chemicals used, farm equipment fuel, transportation fuel, and the fuel required for converting corn to ethanol.